So I start by asking Kevin: “Why are you here?” It’s not some deep existential question; I’m just curious as to the location of Kevin Kay Restorations in Redding, Northern California. “Because it’s not there,’ he shoots back. There being the Bay Area of California south of San Francisco. The Bay Area got too busy and the pace of Northern California was attractive, as is the fly fishing.” We think of California s being defined by Los Angeles, San Francisco and maybe San Diego. But this state is the sith biggest economy in the world and nearly twice the land mass of the UK.

To get to Redding, you fly to San Francisco and head north, past the wine lands, for 230 miles. The scenery flattens out and then the city appears in a plain ringed by snow-capped mountains. The attractions are easy to see, though raging summer heat (40C is common) would take some getting used to. Since moving here in 1986, Kevin has grown to love the area. And for Aston Martin owners across North America, Redding has become synonymous with KKR and Concourse – winning restorations.

So how did it all begin? Kevin was born in Salt Lake City but spent his teenage years in Salt Lake City but spent his teenage years in the 1960s in Greenwich, Connecticut. “As a teen, I would see a lot of the well-to-do locals driving British cars, and though I liked American cars, those European cars seemed pretty cool,” He recalls. A ride in an MG TD heightened his interest, and he bought his first car, a 1962 Triumph TR4, Before he even had his driver’s license. In 1966, his family moved to San Jose at the southern end of what would become Silicon Valley. As a senior in high school he drove an MGA and, when he went to university, a parade of British and European sports cars followed. The itch was scratched and, after university, he worked in a foreign (i.e. mostly British) car parts store in San Jose, which brought him into contact with many British sports car enthusiast. You can see where this is going.

“My manager and I eventually bought the parts business and expanded it to two sites. Somewhat by accident, I got into trading some cars in my spare time, and one of these was a Lotus Cortina that I traded for a 1957 DB2/4, my first Aston.” And it began, but slowly at first. He restored the Aston himself to a very high standard. “When I showed the car at events, other Aston owners asked me who had restored it and asked me to restore their cars.” He also placed an advertisement in a Sacramento newspaper. “Wanted – Aston Martins needing restoration.”

I got six replies and I bought all the cars in various states of disrepair.” Restoring those Astons was “fun”, he says, and kept him busy for several years, further enhancing his reputation, but the demand for his skills was clearly significant and it made sense to have customers pay him for his expertise – especially as there was no dedicated west coast Aston Martin restorer. And so, in 1989, Kevin Kay Restorations was born.

“Right from the start, I focused on ground-up restorations, though in most cases the cars really had to have that level of restoration,” he laughs. “I think what has helped our reputation is that we became known for a “no compromise on quality” attitude. In some cases this may mean a job comes in over budget, but we would not charge the customer for the over-run. That’s the way restorations often go. Issues and complexity take over and the loss of hours can be significant on a job but if the customer was happy then generally we were too. Even after a seven-day week with 12 hours a day.”

In 1995 Mark Wiens and Kevin Baker joined KKR. Mark, somewhat unusually, was not a ‘car nut’ but had huge mechanical skill and is now the shop foreman. Kevin B, on the other hand, is a superb painter, whose work has been on the top step at Pebble Beach. The business has grown further over the past few years and now has 15 employees. Walter Boehringer joined in 2012 and took a financial interest in the company in addition to becoming general manager. As Walter explains: “ I had been a friend and neighbor of Kevin for years, had grown up around classic cars with an uncle showing and judging cars at Pebble Beach, and always had a passion for what he did. When I sold my own hand-tool manufacturing business in 2010 the timing was right for me to step in with Kevin and take an active role in the business.”

Where do you find the staff, I asked Walter. “Hiring people with experience on Aston Martins is not easy. Most often people come to us through word of mouth. With a self-starting attitude, enthusiasm, aptitude and right mentally, we can develop people and make them into valuable team members and restorers. Our core team have been here a long time and new people are trained here by them. “

With the business being in a relatively remote location, it is not surprising that almost all of its skills are in-house and under the same roof. Only trimming is contracted out to a local trimmer who clearly not only has great skill but over the years has acquired an in depth knowledge of the idiosyncrasies of Aston Martin trimming.

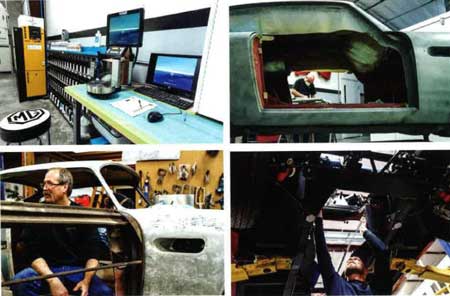

What is surprising is the scale of the facility. Where UK workshops are often quite cramped, this has a real sense of space, with large, dedicated workshops for the various aspects of KKR’s work. The largest are is the servicing and assembly area, though since there are few truly local customers more cars are being restored than serviced. The main workshop also contains extensive racks, where every part taken off a car is neatly stored awaiting its own restoration prior to the time of re-fit.

Looking at a tatty pair of DB4 seats with split leather it seems a shame that they have to be re-trimmed, given all the character and stories that the original material could tell. “Where we can keep original material and the owner wishes to do so, then we certainly will do so,” says Walter, “but all too often something that looks like it can be saved ends up being too decayed to be of use. We understand the argument for preservation alongside restoration, but preservation can be very difficult and most usually impossible, especially with soft material.”

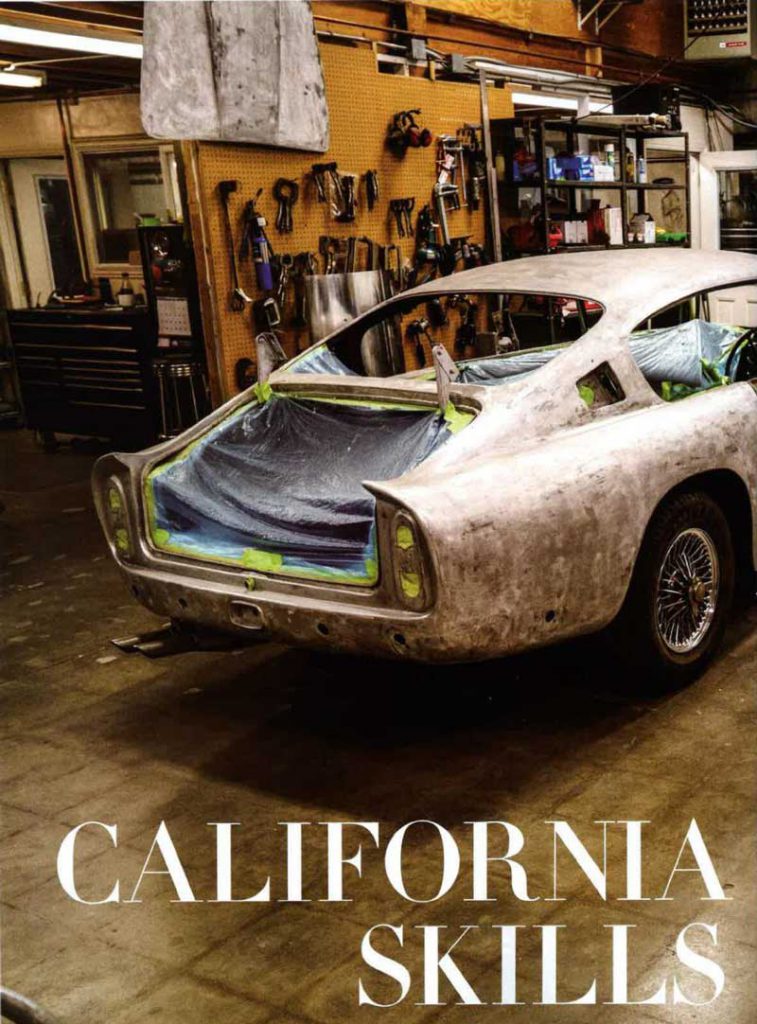

The paint shop is state-of-th-art, with two high-tech booths that constitute one of KKR’s biggest investment. “The standards expected of paint today are incredibly high and we have to be able to satisfy that demand. The irony is that we have been one of the companies to drive that standard up, so we kind of made a rod for our own back!” laughs Kevin. The whole process from bare metal to completion can take up to 900 man-hours, and witnessing the grueling body preparation first-hand, it’s easy to see how the hours accumulate. “Customers love coming here, just to understand how we do our work. In the case of one or two, they want to roll their sleeves up and help!”

One large workshop is dedicated to body repairs and fabrication. A right-hand-drive DB6 is being worked on, the team having discovered pop-riveted patches in the door-skins under copious amounts of filler. As Walter explains: “Cars come to us from all over and we often have to put right previous poor workmanship. This can be a real nightmare because a bad repair is usually far harder to work on than a car that has just been neglected.”

The engine repair and rebuild shop is, as one would expect, immaculately clean. Looking at fully rebuilt DB4 the originality of all the finishes and fixings. Use of modern finishes and modern metal fastenings is not as apparent as it is with some restored engines, and plating is also executed conscientiously with the correct finishes. Where it was dull nickel, It’s re-plated in dull nickel. The effect of this attention to detail is to create and engine that looks perfect but in no way over-restore. Indeed, pretty much how it would have looked with it left the factory.

KKR’s spares department is impressive, with many parts unobtainable elsewhere – usually because the economics of making them don’t work that well! As Walter says: “it’s important that customers can get parts easily through us. Often they want hard-to-find parts, we do everything we can to help them and they seem to appreciate that. Of course, most parts come from England.”

Aston Martins have become the backbone of KKR’s work, with approaching 200 having been restored to one level or another over the last three decades. A remarkable 20 per cent of all DB MKIII Dropheads have passed through these workshops. Customers are, as Kevin puts it, “almost universally nice, interested and easy to work with. Remarkably, they never have a contract with a customer. “ In the early days we never did, so why should we now? There has to be trust in the complex and sometimes unpredictable process of restoring an important car and having trust is much more important than a contract.”

KKR’s reputation is well-founded and customers today come from all over America. So, what has changed over the years? “Where ten or fifteen years ago the restorations were mostly for shows, now the cars are used far more on rallies and tours.” Says Kevin. “ Generally people are using their Astons more. Where the buyer as speculator was once a common thing, nowadays people are buying Astons for long-term pleasure as well as perhaps an investment, and even when they buy as an investment they are often thinking of the car staying in the family for a long time. “People also appreciate cars more for what they are now. They may have a few modest upgrades, but they also respect how the car should be.”

And the secret to KKR’s success? “We have a very high standards here and we want customers to be happy with their cars,” says Kevin. “No matter what the restoration costs, they are happy. It’s hard work but that is why we expend so much energy on the cars. We give them back their car and they are always happy. Always”